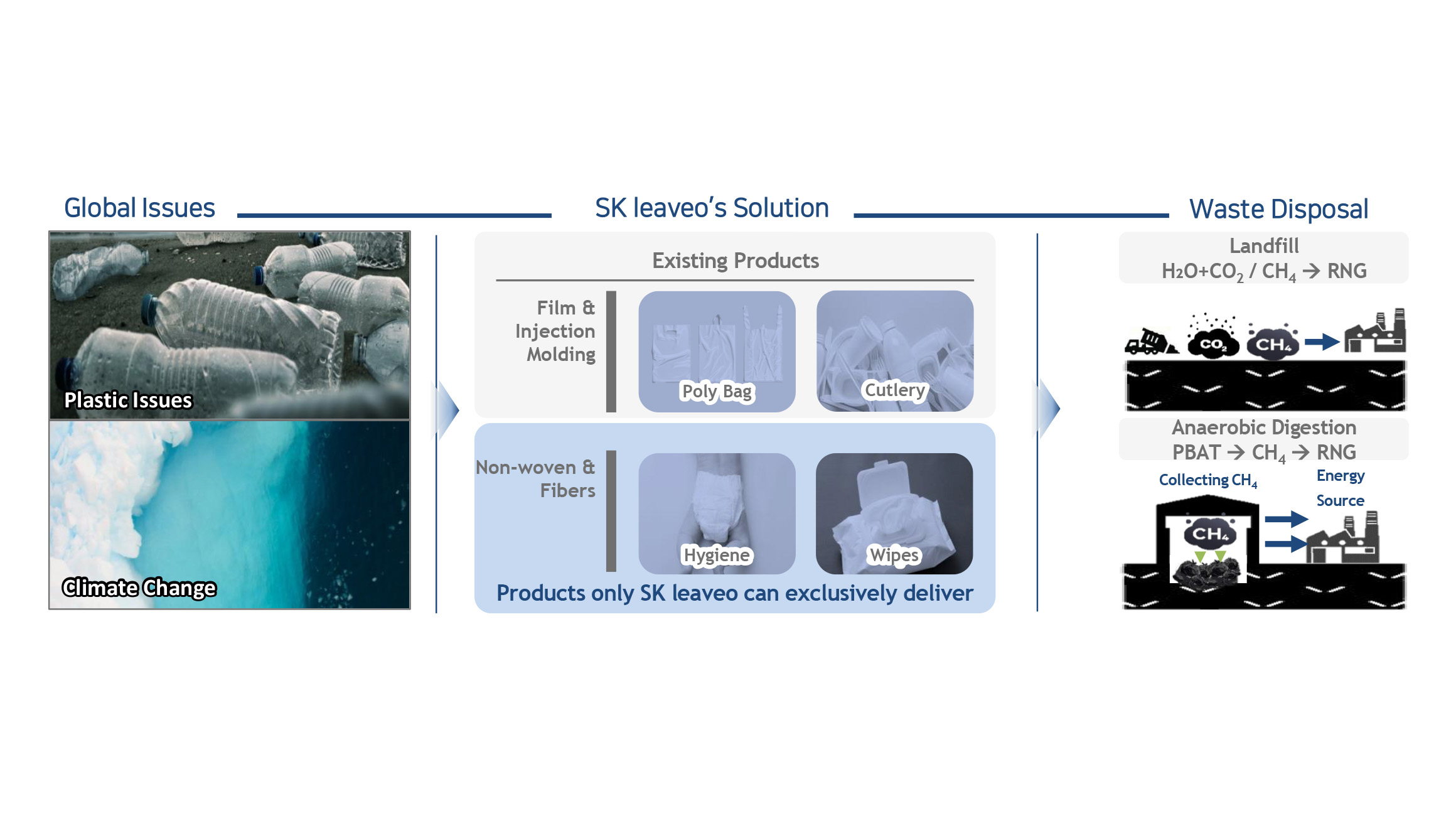

SK leaveo has made groundbreaking advancements in sustainable fiber technology, becoming the first company worldwide to successfully process PBAT (Polybutylene Adipate Terephthalate) into spunbond, meltblown, and staple fiber. This innovation is paving the way for fully biodegradable nonwoven materials, addressing global concerns about plastic waste and environmental sustainability.

SK leaveo is pioneering eco-friendly nonwoven materials with PBAT-based spunbond, meltblown, and staple fibers. Certified by TUV Austria for various biodegradability standards, SK's PBAT degrades more efficiently than conventional alternatives. These fibers offer olefin-like softness with a cool-touch function for comfort and performance. Additionally, research shows the potential for RNG recovery under anaerobic conditions in the deeper layers of the landfill. This innovation proves sustainability and high performance can go together.

David Choi, Sr. Manager of Marketing, SK leaveo Co., Ltd.

Key Achievements:

-

World's First PBAT-Based Spunbond, Meltblown, and Staple Fiber

Spunbond & Meltblown: REICOFIL's industry-leading technology enables SK leaveo to develop high-quality nonwoven materials with efficiency and flexibility, even with entirely new materials like PBAT that have never been tested before. REICOFIL technology ensures both efficiency and quality while offering flexibility to optimize process conditions. With the support of the world's largest nonwoven research lab and expert consultancy, SK leaveo continues to advance the development of high-performance materials.

Staple Fiber: The development is ongoing through pilot and commercial production lines, working closely with manufacturers to optimize fiber properties.

-

Superior Biodegradability of SK leaveo's PBAT: Unlike conventional PBAT, SK leaveo's formulation is certified by TUV Austria for industrial composting, home composting, and soil biodegradability.

This means SK leaveo's PBAT degrades more efficiently than competing PBAT formulations, making it a leading material for sustainable nonwoven/fiber applications.

-

Enhanced Fiber Properties Comparable to Olefins: Nonwovens and fibers made from SK leaveo's PBAT are as soft as olefins, offering superior comfort.

Additionally, they provide a cool-touch function, making them ideal for applications requiring skin-friendly textures.

-

End-of-Life Sustainability & Resource Recovery: SK leaveo's PBAT-based nonwoven/fibers fully biodegrade in composting facilities and contribute to a circular economy by breaking down into water and carbon dioxide.

The company is also accumulating data on how its PBAT degrades in landfills, not just as waste but as a resource for RNG (Renewable Natural Gas) recovery, offering a sustainable alternative to traditional disposal methods.

Through continuous innovation, SK leaveo is setting a new industry standard for eco-friendly nonwoven materials, proving that sustainability and high performance can go together.