Sustainability can sound like a daunting, time-consuming and expensive option when it comes to

production, but it does not have to be. Ultrasonic bonding can help achieve sustainability goals through

multiple factors.

Sustainability is an important part of all our solutions at Herrmann. Ultrasonic technology requires very

little energy compared to thermal or gluing processes and works in such a precise way that rejects are

reduced as much as possible. Easy on resources and efficient. Even today, we are already working on

processing the recyclable, biodegradable and sustainable materials of tomorrow, because ultrasonic

welding is the technology of the future.

Uwe Peregi, President, Herrmann Ultrasonics

Fast, convenient, and economical are just some of the key factors improved when switching to

ultrasonic technology. When thinking about sustainability, think about efficiency in your production.

With the use of Herrmann’s ultrasonic technology, there is an elimination of additional chemicals,

reduction in energy consumption, reduction of waste, and overall resources. Through using ultrasonics,

adhesives are reduced which means machine up time is improved through a reduction of cleaning time

and elimination of heat up and cool down of the machine. All of these factors can help to reduce the

carbon footprint of a company while maintaining the high quality of products.

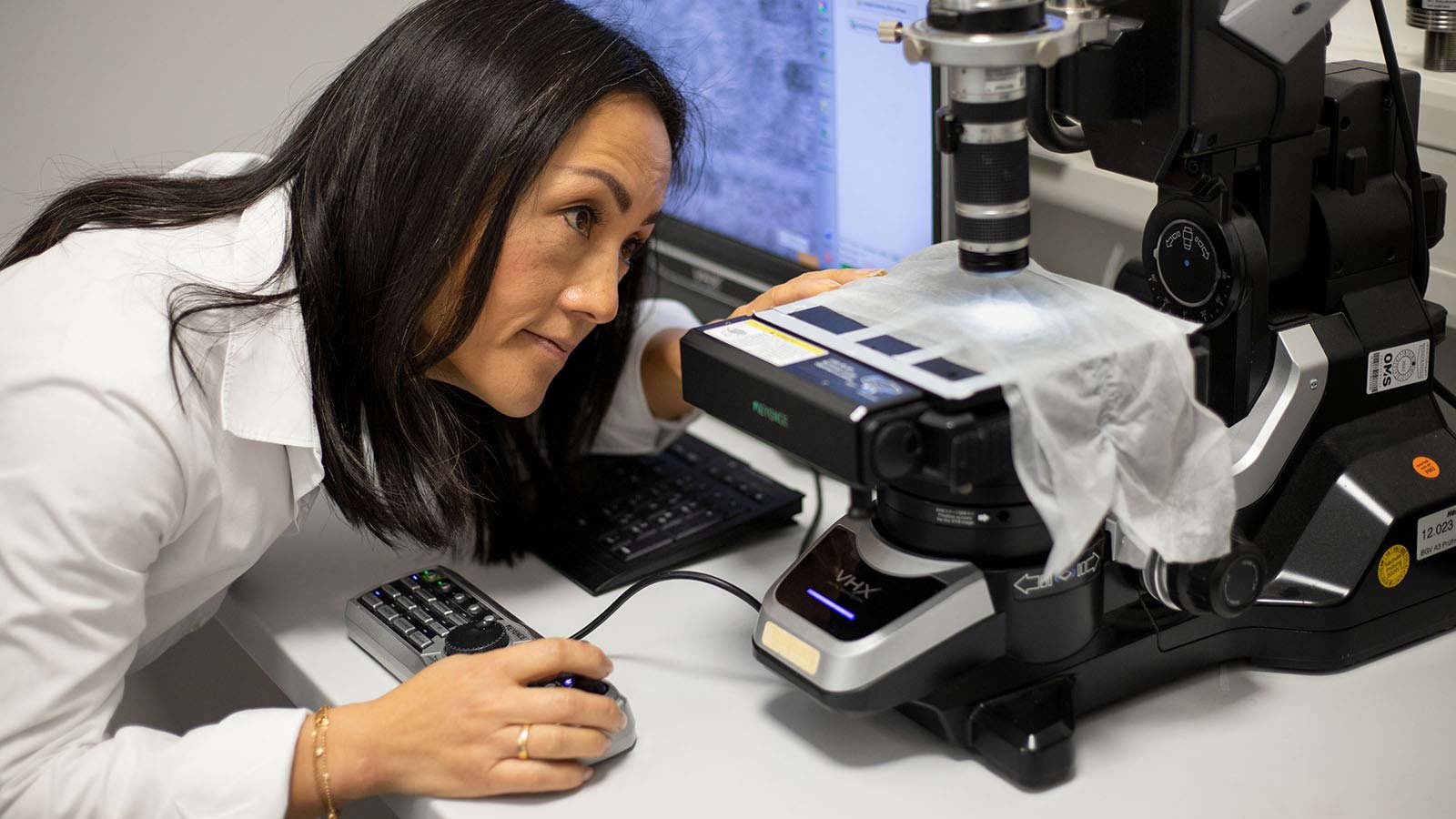

Embodying our motto “Bonding – More than Materials,” Herrmann works closely with our partners

around the world to ensure the highest quality product is produced while continuously improving our

relationships. Our engineers can help you through the production process from material selection to

process integration all the way to the final product by utilizing more than 60 years of ultrasonic

experience and expertise.

How can we support you in your sustainability journey? Find out more: www.herrmannultrasonics.com