The RISE® Innovation Award will recognize innovation in areas within and on the periphery of the nonwovens industry which utilizes advanced science and engineering principles to develop unique or intricate solutions to problems and advance the usage of nonwovens. Nominees will be selected from various disposable and durable product categories and disruptive enabling technologies who exemplify innovation. Areas for consideration include: raw material advances, advances in process or manufacturing technologies including web forming and converting, new product or application development, or other areas that may extend or enhance the use of nonwovens.

Product Eligibility:

Companies are encouraged to nominate their own product(s) for the RISE® Innovation Award, but only one (1) product per company will be selected as a finalist. To qualify for consideration as a nominee for the RISE® Innovation Award, all nominated products must:

-

Be in or on the periphery of the nonwovens field. Examples

include:

- New disposable or durable products or applications that use nonwovens as a major component.

- Advances in web forming technologies.

- Advances in converting or bonding technologies.

- Raw material advances that provide enhanced value to nonwovens: examples might include new fiber, resin, finishing, or additive technology.

- Innovation in manufacturing including inline monitoring and sensing or advanced process control.

- Have been introduced to the market, or to the trade, within the 24 months preceding the event date.

- Not have been selected as a finalist in any previous RISE® Innovation Award competition and not have been a winner of any other INDA award. A nominated product not selected as a finalist or other award winner may be nominated the following year, but no more than two (2) nominations total

- Finalists must agree to present their product in person at the RISE® Conference and to provide a digital 300 dpi/1MB high resolution image of their product for promotional purposes.

Product Criteria:

Nominated products or technologies should demonstrate advancements in one or more of the following categories:

- Creativity (Was there imaginative skill used to create a solution to a known problem?)

- Novelty of approach (Is the method or thought process used to create the product new?)

- Uniqueness (Is this product sufficiently different from others in the marketplace of its type?)

- Technical Sophistication (Does the product/process use nonwoven technology in an intellectually elegant manner?)

Finalist Selection:

The Technical Advisory Board (TAB) of INDA will choose finalists that, in their view, exemplify the use of cutting-edge science and engineering principles to advance the field of nonwovens. If TAB determines that a product or technology nominated for RISE® Innovation Award is better suited for an alternate INDA Award (e.g., HYGIENIX Innovation Award™) TAB will remove the candidate from the list of nominations and submit it for consideration in the applicable award category.

Voting Methodology:

Finalists will present their innovation to the industry at the RISE® Conference. Voting shall be weighted equally across three voting bodies: (1) INDA’s Technical Advisory Board (TAB), (2) the affiliated Conference Committee and (3) the respective registered Conference attendees. Each group shall vote separately and be given equal weight in the final determination of the award winner. Once the weighted votes have been tabulated onsite, the winner will be announced during the scheduled conference hours.

INDA's Technical Advisory Board (TAB), consisting of INDA's President and Technical Director plus industry members with a technical background, shall first select the award finalists from all submissions and then vote on the finalist that best embodies the award criteria. Product scores will be the percentage of TAB votes obtained carried out to two (2) decimal places. INDA personnel will vote on which products make the Finalist category, but not on which shall be the winner of the Award. This will be one-third of the total score for a product finalist.

The Conference Committee, consisting of an INDA staff coordinator and industry members from the market segment of the conference, shall vote on the finalist. Product scores will be the percentage of Committee votes obtained carried out to two (2) decimal places. This will be one-third of the total score for a product finalist. TAB Members on the Conference Committee shall vote only once and INDA staff shall not vote.

The Conference attendees who register and receive a ballot as part of their registration fee shall vote for the finalist. Product scores will be the percentage of the attendee votes obtained carried out to two (2) decimal places. This will be one-third of the total score for a product finalist. TAB members and Conference Committee members shall vote only once either in their specified group or as an attendee.

The winning finalist shall be determined by totaling the voting percentages from the three voting groups and announced during the scheduled conference hours.

Legal disclaimer:

Each company whose products are nominated shall indemnify,

defend, and hold harmless INDA, its directors, officers,

members, employees, and agents, and all other individuals

involved in the voting process from and against any and all

claims, actions, judgments, demands, liabilities, losses,

injuries, costs and expenses arising out of or relating to such

company's products, including the manufacturing, packaging,

labeling, advertising, sale, and use of such products.

Nomination Process

- Complete the Online Nomination Submission

- Send a sample of the product to

INDA, Association of the Nonwoven Fabrics Industry

Atten: Vickie Smead, Advertising & Business Development Associate

1255 Crescent Green, Suite 145

Cary, NC 27518

Categories and rules are based upon the interpretation of the Technical Advisory Board.

Timeline

-

07/28/2025Nomination Deadline

-

08/11/2025Technical Analysis

-

09/01/2025Finalists Announced

-

10/14/2025Finalists' Presentations

-

10/15/2025Winner Announced

RISE® Innovation Award Winners

-

2024: PlantPanel™ – Hempitecture, Inc.

Hempitecture, Inc. won the RISE Innovation Award for their

PlantPanel™ material. PlantPanel™ is a rigid continuous

insulation material used in exterior above-ground

applications. With an R Value of R3.25 per inch, PlantPanel™

adds to thermal and acoustic comfort and performance.

Engineered with a density to resist compression and

deflection, PlantPanel™ is used in split-insulation wall and

roof assemblies with either a rain screen cladding or roofing

material, depending on the application. With 100% biobased and

recycled content, PlantPanel™ is a sustainable, low carbon

continuous insulation solution that's easy to install and safe

to handle.

Hempitecture, Inc. won the RISE Innovation Award for their

PlantPanel™ material. PlantPanel™ is a rigid continuous

insulation material used in exterior above-ground

applications. With an R Value of R3.25 per inch, PlantPanel™

adds to thermal and acoustic comfort and performance.

Engineered with a density to resist compression and

deflection, PlantPanel™ is used in split-insulation wall and

roof assemblies with either a rain screen cladding or roofing

material, depending on the application. With 100% biobased and

recycled content, PlantPanel™ is a sustainable, low carbon

continuous insulation solution that's easy to install and safe

to handle.

-

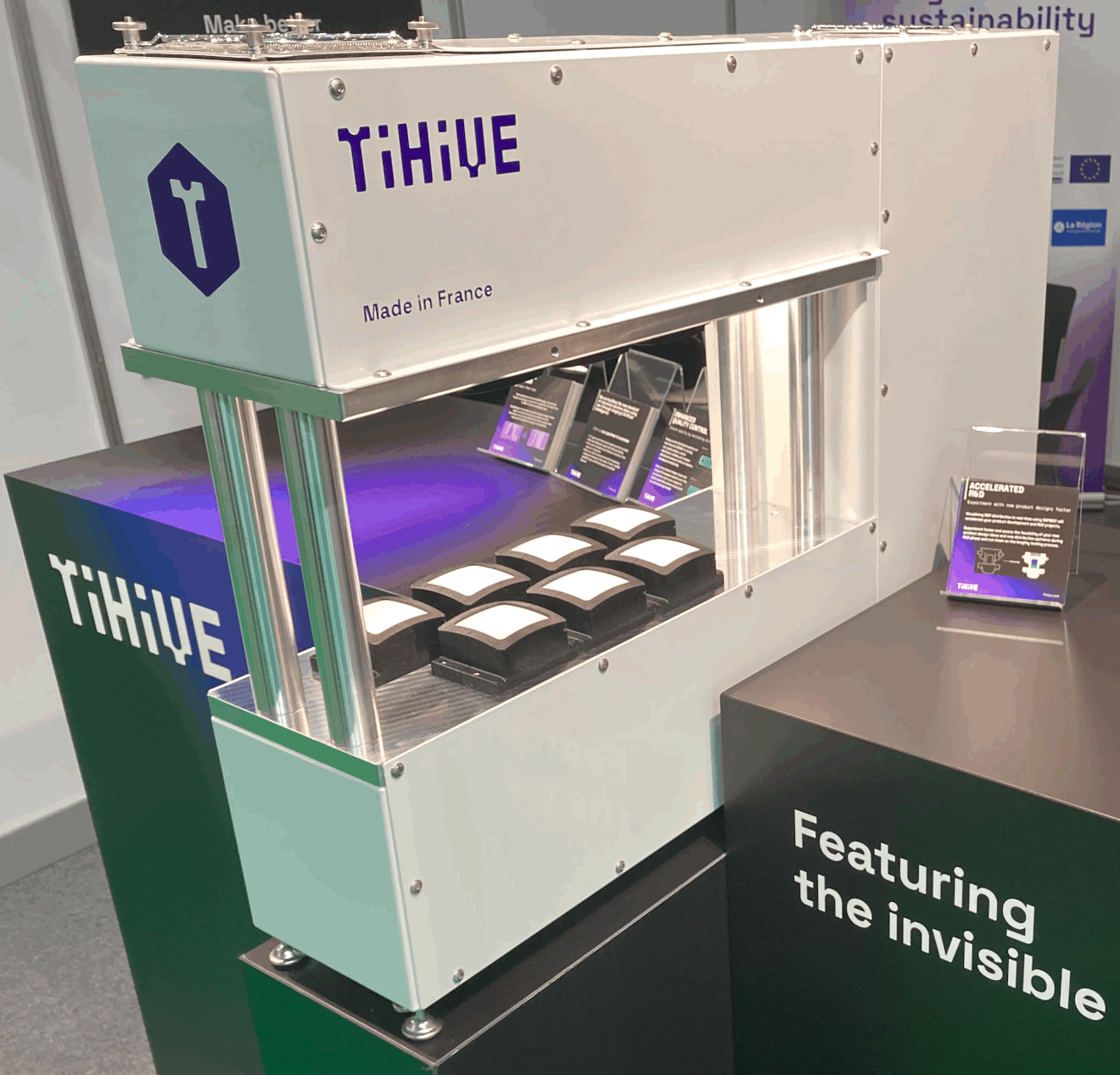

2023: SAPMonit – TiHiVE

TiHive's game-changing innovation, SAPMonit – a visionary

French technology breakthrough – inspects millions of diapers

weekly. SAPMonit delivers lightning-speed inline inspection of

Super Absorbents weight and distribution, optimizes resources,

detects flaws, and accelerates R&D. SAPMonit utilizes advanced

see-through cameras, high-speed vision algorithms, and secure

cloud integration, revolutionizing industry norms. SAPMonit

has great potential for sustainability, cost reduction, and

enhanced customer satisfaction.

TiHive's game-changing innovation, SAPMonit – a visionary

French technology breakthrough – inspects millions of diapers

weekly. SAPMonit delivers lightning-speed inline inspection of

Super Absorbents weight and distribution, optimizes resources,

detects flaws, and accelerates R&D. SAPMonit utilizes advanced

see-through cameras, high-speed vision algorithms, and secure

cloud integration, revolutionizing industry norms. SAPMonit

has great potential for sustainability, cost reduction, and

enhanced customer satisfaction.

-

2022: Cat Litter Made from Recycled Nappies –

DiaperRecycle

DiaperRecycleDiaperRecycle has developed technology to recycle

used diapers into cat litter. The aim of the company is to

make an environmental impact and decrease the climate changing

emissions of diaper waste. They're diverting used diapers

(used in households and businesses such as elder care) from

landfill, separating the plastic and fiber and making cat

litter. The plastic is prepared for recycling by plastics

recyclers. The cat litter product is made by DiaperRecycle

from the super absorbent fiber of diapers; it's highly

absorbent and flushable.

DiaperRecycleDiaperRecycle has developed technology to recycle

used diapers into cat litter. The aim of the company is to

make an environmental impact and decrease the climate changing

emissions of diaper waste. They're diverting used diapers

(used in households and businesses such as elder care) from

landfill, separating the plastic and fiber and making cat

litter. The plastic is prepared for recycling by plastics

recyclers. The cat litter product is made by DiaperRecycle

from the super absorbent fiber of diapers; it's highly

absorbent and flushable.

-

2021: Canopy - Canopy Respirator

Canopy is an innovative respirator that is fully mechanical,

non-electrostatic, with a filter designed for superior

breathability while offering the wearer facial transparency.

The breakthrough respirator features 5.5mm water column

resistance at 85 liters (3 cubic feet) per minute, 2-way

filtration, and a pleated filter that contains over 500 square

centimeters of surface area. The patented Canopy respirator

resists fluids, and eliminates fogging of eyeglasses.

Canopy is an innovative respirator that is fully mechanical,

non-electrostatic, with a filter designed for superior

breathability while offering the wearer facial transparency.

The breakthrough respirator features 5.5mm water column

resistance at 85 liters (3 cubic feet) per minute, 2-way

filtration, and a pleated filter that contains over 500 square

centimeters of surface area. The patented Canopy respirator

resists fluids, and eliminates fogging of eyeglasses.

-

2020: The Nonwovens Institute - Spunbond High Efficiency

Filter

This is a completely new approach to creating a filtration

media with the right efficiency at low pressure drop at high

throughput.

This is a completely new approach to creating a filtration

media with the right efficiency at low pressure drop at high

throughput.

-

2019: Nonwovens Innovation & Research Institute (NIRI) -

Surfaceskins

Hand washing and gel dispensers clean hands, but as soon as a

person touches a door they risk becoming contaminated from a

previous door user. Surfaceskins, antibacterial door push pads

and pull handles, are engineered to kill deposited germs and

bacteria in the vital seconds between one user and the next

passing through the door, thus helping prevent the spread of

some of the germs and bacteria associated with healthcare

associated infections.

Hand washing and gel dispensers clean hands, but as soon as a

person touches a door they risk becoming contaminated from a

previous door user. Surfaceskins, antibacterial door push pads

and pull handles, are engineered to kill deposited germs and

bacteria in the vital seconds between one user and the next

passing through the door, thus helping prevent the spread of

some of the germs and bacteria associated with healthcare

associated infections.

-

2018: DiviDiaper Inc. - DiviDiaper

DiviDiaper prevents/reduces both infant and

Incontinence-associated dermatitis in adults, Urinary Tract

Infections (UTI), Catheter-Associated Urinary Tract Infections

(CAUTI), Candida/yeast/fungal and other genital infections and

pressure sores. It has been recognized by medical staff and

diaper industry leaders as an invaluable innovation.

DiviDiaper prevents/reduces both infant and

Incontinence-associated dermatitis in adults, Urinary Tract

Infections (UTI), Catheter-Associated Urinary Tract Infections

(CAUTI), Candida/yeast/fungal and other genital infections and

pressure sores. It has been recognized by medical staff and

diaper industry leaders as an invaluable innovation.

-

2017: Club Coffee LP - PurPod100™ Compostable Pods

The RISE® Innovation Award was presented to PurPod100™ Compostable Pods made by Club Coffee LP for their certified 100 percent compostable pod for the single-serve coffee process.

"We are truly honored to receive this year's RISE® Innovation Award. Millions of consumers are enjoying a great cup of coffee "guilt-free" in our 100% compostable PurPod100™ format every day, and we are proud to see industry experts recognize the sustainable nonwoven filter innovation that makes every cup possible," said Claudio Gemmiti, Senior VP of Innovation and Strategic Growth at Club Coffee L.P. -

2016: Suominen – Fibrella™ Lite Spunlace

Fibrella Lite is an example of the innovative application of

technology allowing the matching of traditionally

incompatible nonwoven features like softness, strength and

lightweight together in one material, according to the

company. Fibrella Lite nonwovens meet the exacting

requirements for a light yet stretchable material with

strength and elongation properties required in laminates for

absorbent hygiene products in baby care and adult

incontinence applications.

Fibrella Lite is an example of the innovative application of

technology allowing the matching of traditionally

incompatible nonwoven features like softness, strength and

lightweight together in one material, according to the

company. Fibrella Lite nonwovens meet the exacting

requirements for a light yet stretchable material with

strength and elongation properties required in laminates for

absorbent hygiene products in baby care and adult

incontinence applications.

-

2015: Fitesa – 100 Percent Biobased Spunbond

Fitesa, Braskem and NatureWorks engineers have worked

together to produce a new performance nonwoven product

composed of not one, but two biobased polymers in a

sheath-core, bicomponent configuration. The sheath is made

of Braskem's I'm green™ 100% biobased

polyethylene while the core uses NatureWorks' 100% biobased

Ingeo polylactide. The resultant nonwoven is extremely soft,

thanks to the bio-PE outer sheath, yet remains strong and

robust due to the Ingeo core.

Fitesa, Braskem and NatureWorks engineers have worked

together to produce a new performance nonwoven product

composed of not one, but two biobased polymers in a

sheath-core, bicomponent configuration. The sheath is made

of Braskem's I'm green™ 100% biobased

polyethylene while the core uses NatureWorks' 100% biobased

Ingeo polylactide. The resultant nonwoven is extremely soft,

thanks to the bio-PE outer sheath, yet remains strong and

robust due to the Ingeo core.

-

2013: RTI International – NLITe™

Nanofiber Light Improvement Technology

2013: RTI International – NLITe™

Nanofiber Light Improvement Technology

NLITe is a brand new durable nonwoven platform based on emerging technology (nanomaterials) that takes nonwovens into an entirely new market (lighting) where the volume potential is huge -

2012: Ecovative Design – EcoCradle®

EcoCradle is a packaging material that is produced using

mycelium, a fungal network of threadlike cells. This

mycelium grows around agricultural by-products like

buckwheat husks, oat hulls, or cotton burrs to any shape we

make. In 5 – 7 days, in the dark, with no watering, and no

petrochemical inputs, the mycelium envelops the by-products,

binding them into a strong and beautiful packaging part.

Inside every cubic inch of EcoCradle, there's a matrix of 8

miles of tiny mycelial fibers!

EcoCradle is a packaging material that is produced using

mycelium, a fungal network of threadlike cells. This

mycelium grows around agricultural by-products like

buckwheat husks, oat hulls, or cotton burrs to any shape we

make. In 5 – 7 days, in the dark, with no watering, and no

petrochemical inputs, the mycelium envelops the by-products,

binding them into a strong and beautiful packaging part.

Inside every cubic inch of EcoCradle, there's a matrix of 8

miles of tiny mycelial fibers!

-

2011: RKW US, Inc. – Aptra® Elements

New Aptra Elements™ is a metallic, highly

reflective, breathable, air barrier membrane. Made of

durable, UV stabilized polypropylene and nonwoven; the

advanced material maintains strength and flexibility without

metal surface rub-off or oxidation and can be used for

multiple uses within the building, architecture,

construction, marine, tent, and upholstery industries.

New Aptra Elements™ is a metallic, highly

reflective, breathable, air barrier membrane. Made of

durable, UV stabilized polypropylene and nonwoven; the

advanced material maintains strength and flexibility without

metal surface rub-off or oxidation and can be used for

multiple uses within the building, architecture,

construction, marine, tent, and upholstery industries.

The 2024 RISE® Innovation Award went to Hempitecture, Inc. for

their PlantPanel™ material. (l to r) Wes Fisher, INDA Director of

Government Affairs, Matthew Mead, Founder & CEO, Hempitecture, Inc.,

and Matt O'Sickey, Ph.D., INDA Director of Education & Technical

Affairs.

The 2024 RISE® Innovation Award went to Hempitecture, Inc. for

their PlantPanel™ material. (l to r) Wes Fisher, INDA Director of

Government Affairs, Matthew Mead, Founder & CEO, Hempitecture, Inc.,

and Matt O'Sickey, Ph.D., INDA Director of Education & Technical

Affairs.